Final Drive 0BC Removing and Installing, Audi Q5 Hybrid

Special tools and workshop equipment required

- Engine and Gearbox Jack -VAS6931- with Universal Transmission Support -VAG359/2-

- Tensioning Strap -T10038-

- Engine/Gearbox Jack Adapter - Wheel Hub Support - T10149-

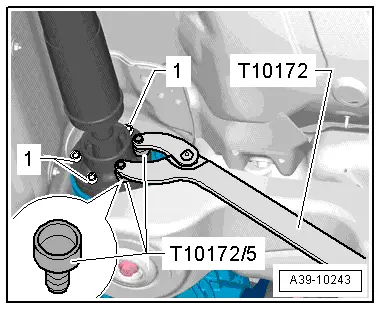

- Counterhold - Kit - Multiple Use -T10172- with Counterhold - Kit - Adapter 5 - T10172/5-

- Socket - Xzn 12 -T40154-

Removal

Pay attention to the safety precautions. Refer to → Chapter "Safety Precautions".

Pay attention to the general repair information. Refer to → Chapter "Repair Information".

- Place the vehicle on a lift.

De-energizing the High-Voltage System

WARNING

WARNING

Follow the High-Voltage System General Warnings. Refer to → Electrical System Hybrid; Rep. Gr.93; High Voltage System General Warnings.

Turning off the voltage in the high-voltage system is carried out exclusively via the Guided Fault Finding on the Vehicle Diagnostic Tester.

DANGER!

DANGER!

Extremely dangerous high-voltage

Electrocution can cause death or severe bodily injury.

- The high-voltage system may only be turned off by qualified personnel (Audi high-voltage technician).

- It must be certain that the high-voltage system is de-energized. The de-energized state is guaranteed only on the Vehicle Diagnostic Tester via "Guided Fault Finding".

- The qualified technician (Audi high-voltage technician) will make sure the voltage is turned off and that the system cannot turn back on again using a Service Disconnect Lock - T40262-. The qualified technician should make sure the system cannot turn on again by keeping the key and the High-Voltage System Maintenance Connector -TW- in a safe place.

- The qualified personnel (Audi high-voltage technician) marks the vehicle with a warning label.

Note

Note

- De-energizing the high-voltage system:

- Connect the Vehicle Diagnostic Tester

- Select the Guided fault finding mode

- Using the Go To button, move through the following menu points

- Function/component selection

- Body

- Electrical Equipment

- OBD-capable system

- 8C - hybrid battery management -J840

- 8C - hybrid battery management, functions

- 51 - De-energize the high-voltage (Repair Group 93) 93)

- Remove the wheel hubcap from the left rear wheel. On alloy wheels, remove the cap using the puller in the vehicle tool kit.

- Remove the left rear wheel.

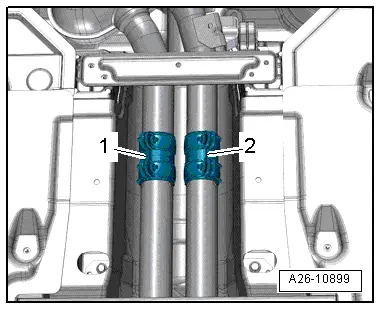

- loosen the clamping sleeves -1 and 2- and remove the rear section of the exhaust system. Refer to → Rep. Gr.26; Exhaust Pipes/Mufflers; Overview - Muffler.

Note

Note

A second technician is needed to help remove the rear section of the exhaust system.

- Remove the driveshaft from the rear final drive. Refer to → Chapter "Drive Shaft, Removing and Installing from Rear Final Drive".

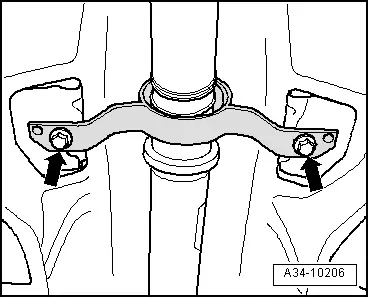

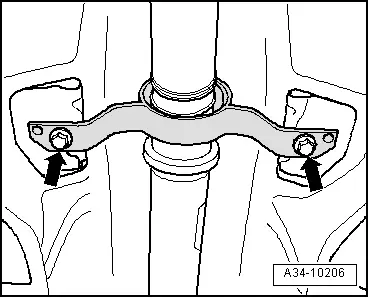

- Remove the driveshaft intermediate bearing mounting bolts -arrows-.

- Push the driveshaft forward and at the same time remove it from the rear final drive.

Note

Note

- The driveshaft is supported by the heat shield under the intermediate bearing.

- The driveshaft can be bent all the way to the center joint without force. Bending the joint forcibly all the way can damage the center joint and/or the protective boot.

- Secure the driveshaft on the side to the subframe.

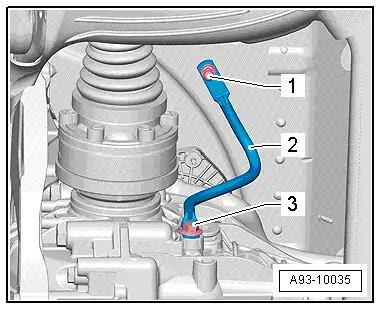

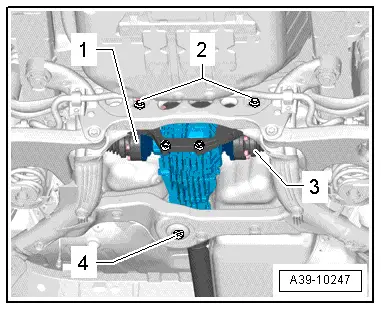

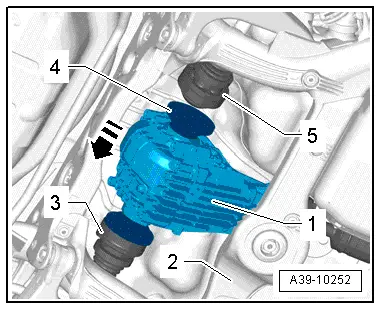

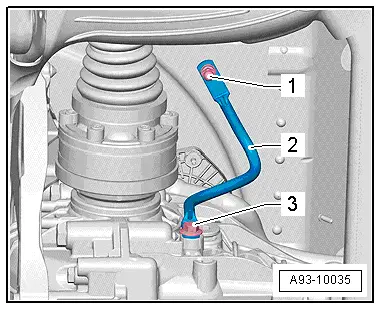

- Remove the bolt -3- for the potential equalization cable -2-.

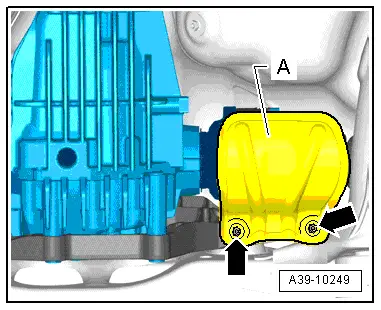

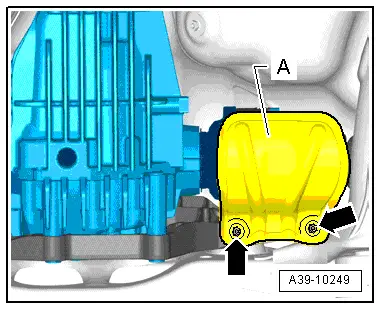

- Remove the left drive axle heat shield -A- from the crossmember/rear final drive-arrows-.

- Remove the left -1- and right -3- drive axles.

- Loosen the bolts -2- approximately three turns.

- Remove the bolt -4-.

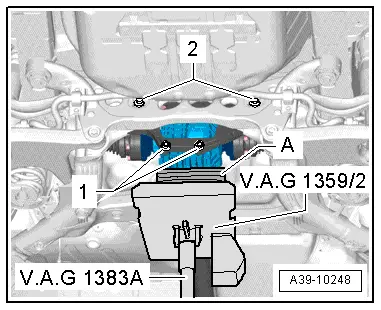

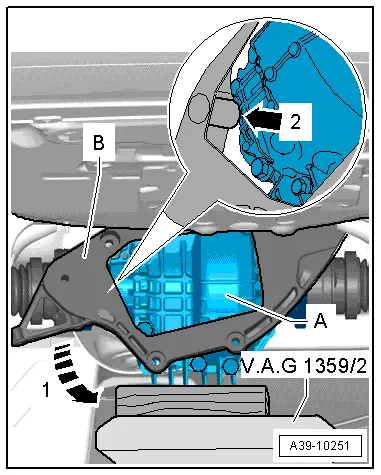

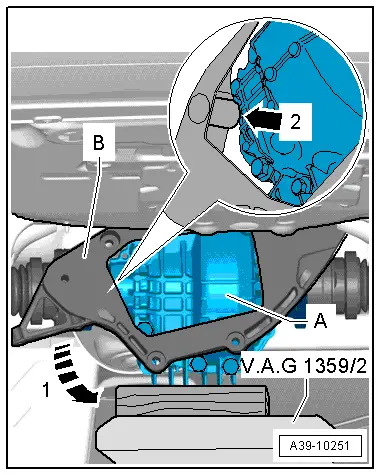

- Position the Engine and Gearbox Jack -VAS6931- and the Universal Transmission Support -VAG1359/2- and a block of wood -A- (approximately 80 mm tall) under the rear final drive.

Note

Note

Pay attention that the Universal Transmission Support -VAG1359/2- does not make contact with the fuel tank.

- Remove the bolts -1- (lower bolts attaching the crossmember to the rear final drive) and -2-.

- Remove the two upper bolts that connect the crossmember -B- to the rear final drive.

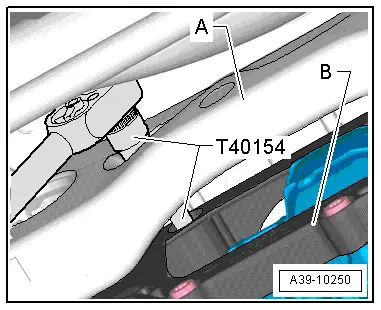

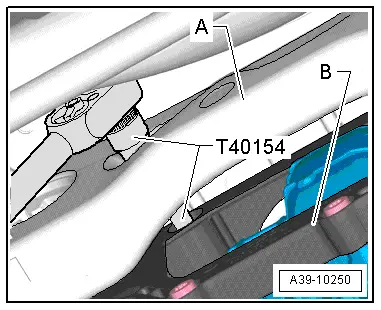

- Guide the Socket - Xzn 12 -T40154- through the holes in the subframe -A-. Move the final drive to the left or right just a little, if necessary.

- Move the final drive -A- forward slightly.

- Turn the lower crossmember -B- direction of -arrow 1- and guide the final drive -arrow 2- and remove it.

Note

Note

- A second technician must help with the next steps.

- Before raising the left rear suspension, secure the vehicle to the lifting arm on the hose using a Tensioning Strap -T10038-.

- Remove the Engine and Gearbox Jack -VAS6931- from under the final drive while a second technician keeps the rear final driving from falling down.

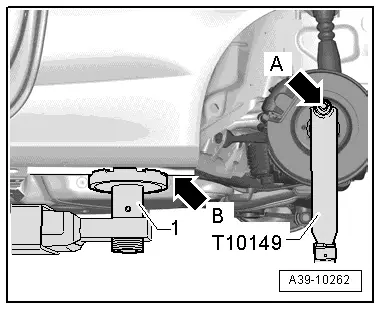

- Insert the Engine/Gearbox Jack Adapter - Wheel Hub Support - T10149- in the Engine and Gearbox Jack -VAS6931-.

- Attach the Engine/Gearbox Jack Adapter - Wheel Hub Support -T10149- using a wheel bolt -arrow A- to the left rear suspension wheel hub.

- Lift the left rear suspension using the Engine and Gearbox Jack -VAS6931- just until the support arm -1- on the vehicle hoist just starts to lift the vehicle -arrow B-.

WARNING

WARNING

- Do not raise or lower the vehicle when the Engine and Gearbox Jack -VAS6931- is underneath it.

- Do not leave the Engine and Gearbox Jack -VAS9631- under the vehicle longer than necessary.

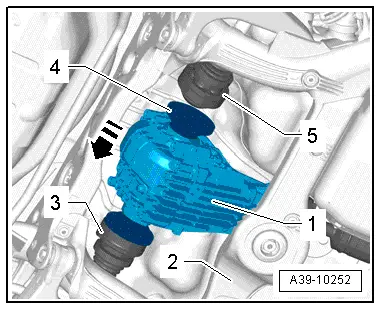

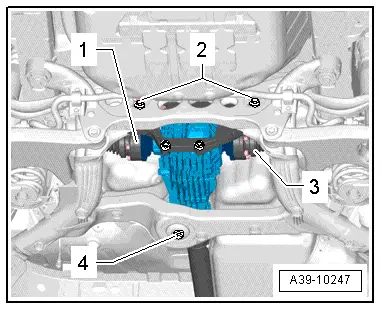

- The second technician must now push the rear final drive -1- toward the left side of the vehicle in direction of -arrow-.

- Then guide the right drive axle -5- upward out of the final drive flange shaft -4-.

- Guide the left drive axle -3- out and then, together with the second technician, remove the final drive from the subframe -2- toward the rear.

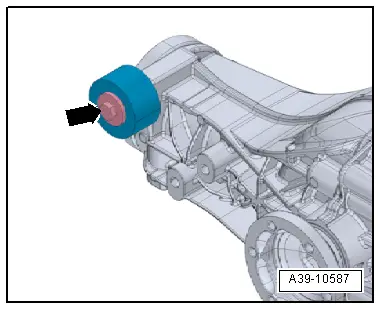

- If the rear final drive is replaced, the balance weight -arrow- must be rebuilt on the new rear final drive.

Installing

Install in reverse order of removal.

WARNING

WARNING

Handling the high-voltage cables:

- Do not stand on or place tools on the high-voltage cables or their components. This may damage the insulation.

- Do not bend or kink high-voltage cables as this may damage the insulation.

- The round high-voltage connectors are color coded with an exterior colored ring and mechanically coded with guide or code tabs. Observe the coding when connecting the round high-voltage connector in order to avoid mechanical damage to the high-voltage connector.

- With a second technician, position the rear final drive -1- on the subframe -2- in its installed position.

- Insert the left drive axle -3- into the final drive flange shaft.

- The second technician must now push the rear final drive -1- toward the left side of the vehicle in direction of -arrow-.

- Then install the right drive axle -5- into the final drive flange shaft -4-.

- Remove the Engine and Gearbox Jack -VAS6931- with the Engine/Gearbox Jack Adapter - Wheel Hub Support -T10149- from the left rear suspension.

- Position the Engine and Gearbox Jack -VAS6931- and the Universal Transmission Support -VAG1359/2- and a block of wood (approximately 80 mm tall) under the rear final drive -A-.

- Move the final drive -A- forward slightly.

- Turn the upper crossmember -B- opposite the direction of -arrow 1- to the left and insert it while guiding it past the final drive -arrow 2-.

- Tighten the four bolts connecting the crossmember -B- to the rear final drive diagonally. Tightening specification. Refer to -item 4-.

- Guide the Socket - Xzn 12 -T40154- through the holes in the subframe -A-. Move the final drive to the left or right just a little, if necessary.

- First tighten the bolt -2 and 4- hand-tight.

Note

Note

For better illustration the Engine and Gearbox Jack -VAS6931- with the Universal Transmission Support -VAG1359/2- are not shown.

- Tighten the bolt -4-. Tightening specification. Refer to -item 3-.

- Tighten the bolts -2-. Tightening specification. Refer to -item2-.

- Remove the Engine and Gearbox Jack -VAS6931- from under the final drive.

- Tighten the left -1- and right -3- drive axles. Refer to → Suspension, Wheels, Steering; Rep. Gr.42; Drive Axle; Drive Axle, Removing and Installing.

- Tighten the potential equalization cable -2- to the rear final drive.

- Bolt tightening specification -3- on the final drive: 20 Nm

- Attach the left drive axle heat shield -A- to the crossmember/rear final drive -arrows--item 6-.

- Attach the driveshaft to the rear final drive.

- Attach the driveshaft intermediate bearing to the body free of tension. Tightening specification. Refer to -item 8-.

- Check the gear oil level in the rear final drive. Refer to → Chapter "Gear Oil, Checking Level, 0BC".

- Install the rear section of the exhaust system and align it so it is free of tension. Refer to → Rep. Gr.26; Exhaust Pipes/Mufflers; Overview - Muffler.

- Install the left rear wheel and tighten. Refer to → Suspension, Wheels, Steering; Rep. Gr.44; Wheels and Tires; Wheel Bolt Tightening Specifications.

Energizing the High-Voltage System

Only by using the Guided Fault Finding in the Vehicle Diagnostic Tester can the high-voltage system be restarted.

DANGER!

DANGER!

Extremely dangerous high-voltage

Electrocution can lead to severe bodily injury or death

- The high-voltage system may only be re-energized by qualified personnel (Audi high-voltage technician).

- Only the Vehicle Diagnostic Tester via "Guided Fault Finding" can guarantee if the system has been re-energized.

- The qualified personnel (Audi high-voltage technician) restarts the vehicle.

- The qualified personnel (Audi high-voltage technician) marks the vehicle with a warning label.

Note

Note

- Energizing the high-voltage system:

- Connect the Vehicle Diagnostic Tester

- Select the Guided fault finding mode

- Using the Go To button, move through the following menu points

- Function/component selection

- Body

- Electrical Equipment

- OBD-capable system

- 8C - hybrid battery management -J840

- 8C - hybrid battery management, functions

- 51 - High-voltage re-energizing (Rep.Gr. 93)