Audi Q5: All Wheel Drive Pump -V415-, Removing and Installing

All Wheel Drive Pump -V415-, Removing and Installing, 0BE, 0BF

Special tools and workshop equipment required

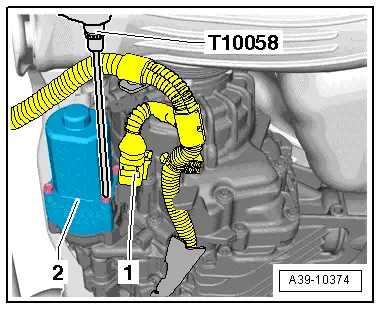

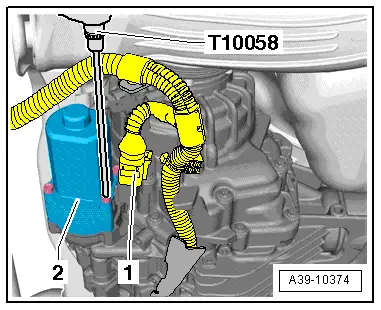

- Hex Ball Socket -T10058-

Note

Note

- Pay attention to the general repair information. Refer to → Chapter "Repair Information".

- Pay attention to the safety precautions. Refer to → Chapter "Safety Precautions".

Removing

- Place the vehicle on a lift.

- The ignition is off.

- Place the Drip Tray under the rear final drive.

- Disconnect the connector -1- from the All Wheel Drive Pump -V415--2-.

- Remove the four bolts that connect the All Wheel Drive Pump -V415- to the hydraulic control unit using the Hex Ball Socket -T10058-.

- Carefully remove the All Wheel Drive Pump -V415--2-. Pay close attention to the adapter -item 4- inside the hydraulic pump while doing this.

Note

Note

- The adapter could fall out when removing the All Wheel Drive Pump -V415-.

- Insert the adapter into the recesses in the hydraulic pump before installing the All Wheel Drive Pump -V415-.

Installing

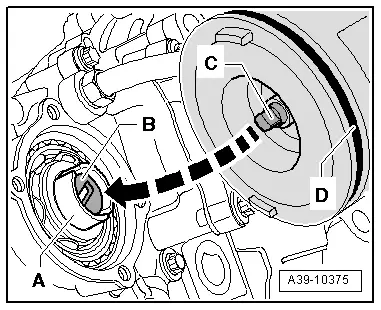

- The hydraulic pump -A- is installed inside the hydraulic control unit. Assembling the hydraulic pump. Refer to → Fig. "Assembling the Hydraulic Pump".

- The adapter -B- is installed in the recesses in the hydraulic pump.

- A new O-ring -D- is on the All Wheel Drive Pump -V415-.

- Install the All Wheel Drive Pump -V415- with the coupling -C- in the adapter -B-.

- Diagonally tighten the four bolts on the All Wheel Drive Pump -V415--2- to the tightening specification -item 1-.

- Connect the connector -1- to the All Wheel Drive Pump -V415-.

- Fill the ATF in the rear final drive. Refer to → Chapter "ATF, Filling, 0BE, 0BF".