Audi Q5: Overview - Lower Control Arm and Ball Joint

Audi Q5 Type 8R (2008 - 2017) Service Manual / Chassis / Suspension, Wheels, Steering / Front Suspension / Overview - Lower Control Arm and Ball Joint

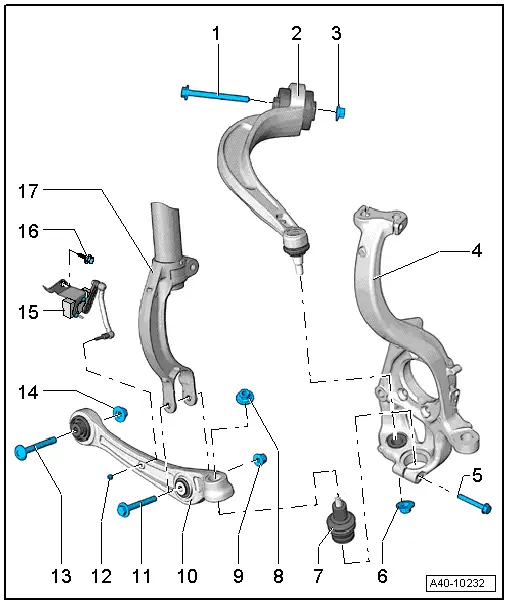

1 - Bolt

- Always replace if removed

2 - Guide Link

- Removing and installing. Refer to → Chapter "Guide Link, Removing and Installing".

- There are conventional and hydraulic bonded rubber bushings. For the correct allocation. Refer to the Parts Catalog

- Conventional Bonded Rubber Bushing for Guide Link, Replacing, 65 mm diameter. Refer to → Chapter "Guide Link Bonded Rubber Bushing, Removing and Installing, Standard Bonded Rubber Bushing 65 mm Diameter".

- Replacing the hydraulic bonded rubber bushing 75 mm for the guide link. Refer to → Chapter "Guide Link Bonded Rubber Bushing, Removing and Installing, Hydraulic Bonded Rubber Bushing 75 mm Diameter"

3 - Nut

- 70 Nm +180º

- Always replace if removed

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

4 - Wheel Bearing Housing

5 - Bolt

- 40 Nm

- Always replace if removed

6 - Nut

- Always replace if removed

- There are different versions. For allocation. Refer to the Parts Catalog.

- There are different versions and tightening specifications.

- After loosening threaded connection of guide control arm to wheel bearing housing, adhesive residue must be removed on thread of linkage stub.

7 - Ball Joint

- Removing and installing. Refer to → Chapter "Ball Joint, Removing and Installing".

- There are different versions. For allocation. Refer to the Parts Catalog.

Note

Note

- Note the installation position.

- Install the ball joint into the wheel bearing housing as far as the contact surface.

8 - Nut

- There are different versions. For allocation. Refer to the Parts Catalog.

- There are different versions and tightening specifications.

- Always replace if removed

- After loosening threaded connection on the ball joint to the wheel bearing housing, adhesive residue must be removed on thread of linkage stub.

9 - Nut

- 90 Nm +90º

- Always replace if removed

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

10 - Control Arm

- Removing and installing. Refer to → Chapter "Control Arm, Removing and Installing".

- There are different versions. For allocation. Refer to the Parts Catalog.

- Replacing bearings for track control arm. Refer to → Chapter "Control Arm Ball Bearing, Replacing"

11 - Bolt

- Always replace if removed

12 - Nut

- 9 Nm

13 - Bolt

- Always replace if removed

14 - Nut

- 70 Nm +180º

- Always replace if removed

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

15 - Left/Right Front Level Control System Sensor -G78-/-G79-

- Only sensors of the same version may be installed.

- Only remove and install or replace completely. Refer to → Chapter "Left/Right Front Level Control System Sensor -G78-/-G289-, Removing and Installing".

- The sensor lever must point toward the back

- The headlamp basic setting must be checked after loosening. Refer to → Electrical Equipment; Rep. Gr.94; Headlamps; Headlamp, Adjusting.

- If the level control system sensor was removed and installed on a vehicle with electronically controlled damping or if the linkage was loosened, the control position must be reprogrammed using the Vehicle Diagnostic Tester. Refer to → Chapter "Control Position, Programming".

- If the control position was reprogrammed on vehicles with lane assist, the Directional Stabilization Assistance Control Module -J759- must be calibrated again. Refer to → Chapter "Lane Assist, Calibrating".

16 - Bolt

- 20 Nm

17 - Shock Absorber Fork

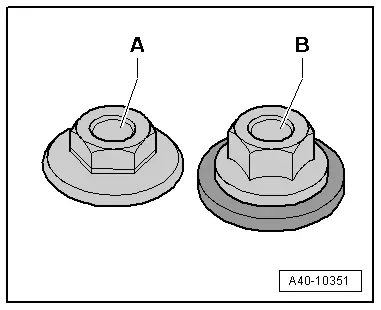

Nut versions for the control arm and guide link bracket

- Hex - collar nut -A- M12 wrench 21 mm

Tightening specification: 145 Nm

- Hex - combination nut -B- M12 18 mm

Tightening specifications: 110 Nm

- Hex - combination nut -B- M12 21 mm

Tightening specification: 120 Nm

- Hex - combination nut -B- M14 21 mm

Tightening specification: 140 Nm