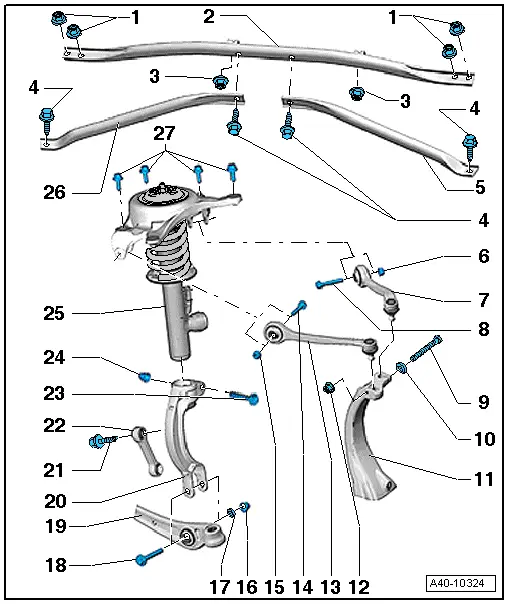

Audi Q5: Overview - Suspension Strut and Upper Control Arm

Audi Q5 Type 8R (2008 - 2017) Service Manual / Chassis / Suspension, Wheels, Steering / Front Suspension / Overview - Suspension Strut and Upper Control Arm

1 - Nut

- 20 Nm

2 - Tower Brace

- Removing and installing. Refer to → Chapter "Tower Brace, Removing and Installing".

3 - Nut

- 2 Nm

4 - Bolt

- 20 Nm

5 - Left Additional Reinforcement

- Removing and installing.

6 - Nut

- 50 Nm +90º

- Always replace if removed

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Push toward the inside of the vehicle when tightening the control arm

7 - Upper Rear Control Arm

- Removing and installing. Refer to → Chapter "Upper Control Arm, Removing and Installing".

- There is a bonded rubber bushing with a different rubber mixture installed in the top of the control arm. Allocation. Refer to the Parts Catalog. Installing more than one kind is not permitted.

8 - Bolt

- Always replace if removed

9 - Bolt

- Always replace if removed

10 - Washer

11 - Wheel Bearing Housing

12 - Nut

- 40 Nm

- Always replace if removed

13 - Upper Front Control Arm

- Removing and installing. Refer to → Chapter "Upper Control Arm, Removing and Installing".

14 - Bolt

- Always replace if removed

- There is a bonded rubber bushing with a different rubber mixture installed in the top of the control arm. Allocation. Refer to the Parts Catalog. Installing more than one kind is not permitted.

15 - Nut

- 50 Nm +90º

- Always replace if removed

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Push toward the inside of the vehicle when tightening the control arm

16 - Nut

- 90 Nm +90º

- Always replace if removed

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

17 - Washer

18 - Bolt

- Always replace if removed

19 - Control Arm

20 - Shock Absorber Fork

- Shock Absorber Fork, Removing and Installing. Refer to → Chapter "Shock Absorber Fork, Removing and Installing"

21 - Bolt

- 40 Nm +90º

- Always replace if removed

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

22 - Coupling Rod

- Note the installed position. Refer to → Chapter "Coupling Rod, Removing and Installing".

- There are versions made of aluminum and plastic. For allocation. Refer to the Parts Catalog

- A mixed installation is not permitted

23 - Bolt

- 40 Nm +180º

- Always replace if removed

24 - Nut

- Always replace if removed

25 - Suspension Strut

- Suspension strut with mounting bracket, removing and installing. Refer to → Chapter "Suspension Strut, Removing and Installing".

- Suspension strut with mounting bracket, servicing. Refer to → Chapter "Suspension Strut, Servicing".

- There are different versions of the suspension. Refer to → Chapter "Explanations of Production Control Numbers (PR Number)".

- Always vent and drain faulty shock absorbers before disposal. Refer to → Chapter "Repair Information".

- Shock Absorber, Checking. Refer to → Chapter "Repair Information".

26 - Right Additional Reinforcement

- Removing and installing.

27 - Bolt

- 40 Nm +90º

- Note the tightening sequence.

- Always replace if removed